Leading Innovative Pharmaceuticals Production in Georgia

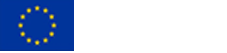

Founded in 1999, JSC BioChimPharm (BCP) is a Georgian-based, biotechnology SME engaged in R&D

Read MoreDownload

Testing Services for Georgian Exporters

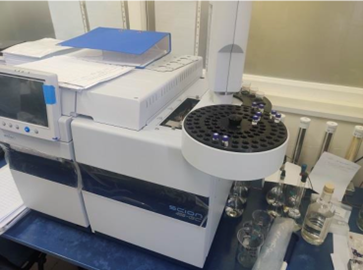

The “LTD Eye Microsurgery Javrishvili Clinic – Oftalmiji” clinic was founded in 1996 and provides

Read MoreDownload

Greener Paper Products

Neoprint LLC has been providing customers in Georgia,

Read MoreDownload

Eye Treatment Services

The “LTD Eye Microsurgery Javrishvili Clinic – Oftalmiji” clinic was founded in 1996 and provides

Read MoreDownload

Modernization of construction equipment

Arali is a relatively new company that lets and sells mobile and stationary equipment to

Read MoreDownload

Refitting the turbines of a Hydropower station in Georgia

The hydropower station, owned by the company KCIA-94,

Read MoreDownload

Gurjaani Ice Cream Factory

Traditional Ice cream manufacturer Invested in the construction of a new production building and purchase of a new Ice cream production.

Read MoreDownload

Ambassadori Kachretshi

Ambassadori Hotel Kachretshi is an ideal place for that vacation everyone craves to escape from their busy lives.

Read MoreDownload

High quality sweets made in Georgia

LTD Brauni was founded in April 2017 in Tbilisi, Georgia. The company produces high-quality confectionery products,

Read MoreDownload

Putting Georgia on the Coffee Map

MEAMA, the first ever Georgian coffee brand was established in 2016 with the goal of offering high quality locally roasted coffee,

Read More Download